Mimaki puts the pedal to the metal for Internet of Things

- Publicado el 08 de Julio de 2019

Process automation and Internet of Things (IoT) are widely recognised as new powerful tools that manufacturers could be leveraging to boost efficiency in production and increase revenue. Mimaki keeps at the forefront of industry innovation, demonstrating how integration and automation in printing production processes can enable print service providers to take their businesses to the next level. Utilising Mimaki’s R&D leadership in advanced workflow automation, together with collaborations with automation experts outside of the industry, the company has been able to create a truly integrated and automated UV LED print production line.

“A pioneer in digital printing, Mimaki has already embraced the countless possibilities of IoT and is now taking full advantage of it,” comments Uwe Niklas, General Sales Manager, Mimaki Deutschland GmbH. “This IoT-based R&D strategy has led the company to develop advanced printing systems able to communicate with robots, as well as with a wide range of hardware including belt conveyors, inspection devices and cutting machines. The objective is to make it possible for print service providers to incorporate inkjet printers in fully-connected industry 4.0 production lines, ultimately enabling unattended on-demand production and mass customisation. This is how Mimaki sees the future of digital printing.”

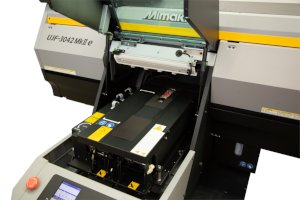

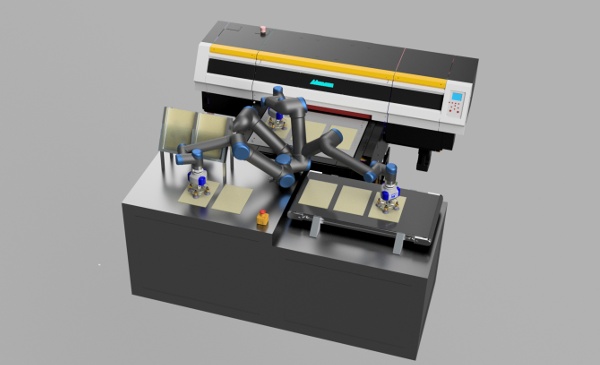

With the aim of helping customers to take on board a new vision for future growth, Mimaki provides live demonstrations of integrated processes in its showroom in Munich and at trade shows. Mimaki has developed the IoT automation within a UV LED inkjet printing process with the collaboration of German company Robominds. The ground-breaking production line features a Mimaki UJF-7151plus compact direct inkjet printer combined with a robotic arm by Danish firm Universal Robots (distributed in Germany by Robominds). Uniquely, the robotic arm loads and unloads substrates from the printer, without any human intervention.

Communication and information exchange between Mimaki's UJF-7151plus and the robotic arm are made possible by the IoT-based interface Job Controller IP

The communication and information exchange between the UJF-7151plus and the robotic arm is enabled by a Mimaki IoT-based interface, called Job Controller IP, which is also available with Mimaki’s current JFX series. “Utilising our long history of developing state-of-the-art workflow management software, we were able to design our own advanced yet user-friendly solution. As an IoT interface, Job Controller IP is extremely easy to install and use – boosting production efficiency and flexibility levels within the print production workflow. The incredible in-house technical capabilities at Mimaki enabled us to successfully integrate robotics within the print production workflow, and achieve unmanned operation,” says Niklas.

The choice of robotic arm from Robominds has also contributed to Mimaki’s ability to deliver top-level performance: a six-axis robot, it features a modular design which makes it suitable for all kinds of printed products. In addition, the robot is compact, so it does not require any extra space, and is safe, as it stops as soon as someone touches it. Featuring four degrees of movement, the Robominds robot is also equipped with suction cups that enable it to handle different substrates.

For all print service providers, no matter their size, the market they serve or the inkjet solution they use, the benefits of integrating IoT automation into their production lines is significant. These benefits range from increased productivity and print capacity, to flexibility in materials handling and reduced machine make-ready times. For visitors to trade shows, Mimaki is showing them how they can enhance their business performance by getting their printing platforms and related hardware ‘intelligently’ connected – to ultimately increase their profitability.

“Providing a new level of production efficiency, the proof of concept robotic demonstration is aimed at offering customers a glimpse into the future of inkjet print production for wide format applications and beyond,” concludes Niklas.

A rendering of Mimaki's UJF-7151plus with the six-axis robot, which loads and unloads substrates from the printer without any human intervention